A lifecycle assessment (LCA)—also sometimes styled life cycle assessment—is a standardized, science-based method used to evaluate the environmental impacts of a product, service, or process from start to finish. It takes into account all the stages of a product’s life: from raw material extraction and manufacturing, through transportation and usage, to final disposal or recycling.

As a comprehensive framework, LCA helps businesses in different industrial sectors quantify environmental impacts in terms of resource use, emissions, waste, and ecological damage. It supports better decision-making, sustainable innovation, and regulatory compliance.

Why lifecycle assessment matters

LCAs have become essential in the shift toward responsible production and consumption. Stakeholders—from regulators and investors to customers and supply chain partners—are demanding greater transparency about the environmental footprint of products and operations. An LCA provides the data needed to answer those questions clearly and credibly.

Crucially, lifecycle assessment isn’t just about compliance; it drives better business performance by uncovering opportunities to reduce costs, emissions, and material waste. Such analysis enables organizations to make more informed decisions regarding sustainability by providing critical environmental data across all stages of a product’s life cycle. For companies aiming to lead in sustainability, LCA is both a baseline and a benchmark.

What an LCA measures

An LCA examines both the inputs and outputs at every life stage. Inputs may include raw materials, energy, water, and chemicals. Outputs cover emissions to air, water, and soil; solid waste; and by-products.

A crucial part of the process is life cycle inventory analysis, where companies collect data on all relevant environmental flows. The data is then analyzed to assess potential environmental impacts across each impact category, such as climate change, human health, resource depletion, acidification, acid rain, and other environmental indicators. LCA studies evaluate these potential environmental impacts to provide a comprehensive understanding of a product’s ecological footprint.

International environmental management standards, particularly ISO 14040 and ISO 14044, provide the methodological framework for conducting LCAs. These standards help standardize LCA studies and ensure that assessments are consistent, transparent, and credible—whether for internal use, stakeholder reporting, or regulatory submissions.

Lifecycle assessment vs. product carbon footprint

While both lifecycle assessments and product carbon footprints (PCFs) aim to quantify environmental impact, their scope and depth differ significantly.

Lifecycle assessment (LCA)

An LCA takes a multi-dimensional approach. It evaluates a wide range of environmental impact categories such as:

- Greenhouse gas emissions

- Water use

- Land use

- Resource depletion

- Eutrophication

- Acidification

- Human health risks

By assessing these areas, LCAs provide a holistic understanding of a product or process’s environmental performance.

Product carbon footprint (PCF)

A PCF focuses exclusively on greenhouse gas emissions—usually measured in CO₂-equivalent units—over the product’s lifecycle. It helps organizations understand their contribution to climate change but lacks the broader environmental scope of an LCA.

In essence, a PCF is a subset of an LCA, suitable for carbon-focused goals but insufficient for comprehensive environmental strategy.

Who uses lifecycle assessments?

LCAs are useful across multiple business functions and different industrial sectors:

Product design and R&D

Lifecycle assessments help engineers and designers choose sustainable materials, design for reuse or recycling, and reduce the product’s environmental impact from the ground up. Evaluating each value added process in the product design cycle can help identify opportunities for environmental improvement. By modeling design choices with LCA data, teams can innovate more responsibly.

Supply chain and procurement

LCAs offer a framework for evaluating suppliers and sourcing strategies. Since supply chains often account for a large portion of a product’s footprint, assessing upstream raw material impacts can yield significant sustainability gains.

Marketing and communications

Verified LCA data enhances the credibility of environmental claims. As greenwashing concerns grow, transparent and scientifically grounded data is essential in marketing messaging and stakeholder reporting.

Executives and strategic planners

At the strategic level, LCAs identify impact “hotspots” across business operations, helping leadership focus resources on the most effective sustainability interventions. This not only improves performance but also builds brand trust and resilience.

Compliance and reporting teams

With tightening environmental regulations, LCAs help meet reporting obligations and contribute to disclosure frameworks like the EU Taxonomy, CSRD, and the SEC’s proposed climate disclosures.

Industry-wide assessments

Beyond individual companies, lifecycle assessments are used in different industrial sectors to define benchmarks, product category rules, and sector-wide decarbonization strategies.

Types of lifecycle assessments

LCAs vary depending on the product or system being evaluated and the system boundaries selected. Defining the system boundary is crucial for determining which life cycle stages and parts of the production chain are included in the assessment. Here are the most common LCA types:

Cradle-to-grave

Covers the full lifecycle—from raw material extraction (cradle) to disposal or end-of-life treatment (grave), including the disposal phase where the product is discarded, incinerated, or recycled. This is the most comprehensive form of LCA, often used for product comparisons and regulatory disclosures.

Cradle-to-gate

Assesses impacts from resource extraction up to the point the product leaves the manufacturing facility, a process known as cradle to gate analysis. This is a common form of cradle to gate assessment, especially for B2B companies or manufacturers supplying intermediate goods.

Gate-to-gate

Focuses on a specific segment of the production process. This is helpful for optimizing individual processes within a larger system and often used when full LCA data is not yet available.

Cradle-to-cradle

An extended approach that considers product reuse and recycling, emphasizing closed-loop systems and the circular economy. Through the recycling process, products can enter a new life cycle, extending their environmental and economic value. This model supports the idea that end-of-life can be the beginning of a new lifecycle.

Well-to-wheel

Frequently used in the transportation and energy sectors, this assesses the full impact of fuel production and energy use in vehicles. This includes both well to tank (upstream fuel production and transmission) and tank to wheel (vehicle operation) stages, allowing for detailed analysis of energy production and energy usage throughout the lifecycle.

Economic input-output LCA (EIO-LCA)

Uses economic data to estimate environmental impacts across large systems, especially when specific process data is lacking. It’s especially useful for sectoral analysis or assessing national economies.

Product Environmental Footprint (PEF)

Developed by the European Commission, PEF is a standardized LCA-based methodology that enables cross-industry comparison of environmental impacts using uniform rules.

The four main stages of an LCA

Lifecycle assessments are structured around four key phases, as defined by ISO 14040 and ISO 14044. These stages ensure the LCA is systematic, repeatable, and actionable.

Stage 1: Goal and scope definition

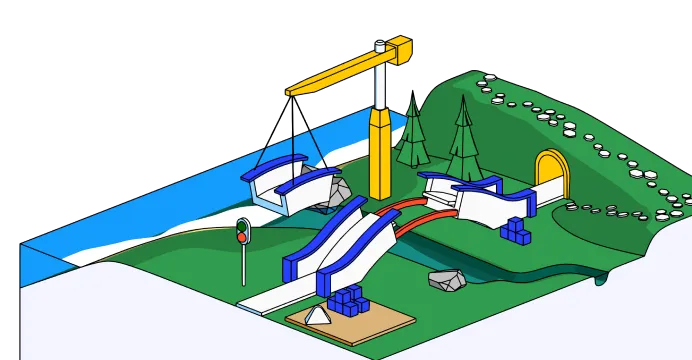

This stage defines the purpose of the LCA, the functional unit (e.g., per kilogram of product), and the system boundaries (which stages and processes will be included). Defining the technical system and creating a flow model are important steps at this stage, as they clarify the scope and structure of the LCA by visually representing the system’s boundaries, inputs, outputs, and processes. It also determines the intended audience and expected outcomes.

Stage 2: Life cycle inventory (LCI) analysis

The most data-intensive stage, LCI involves collecting data on inputs (e.g., water, electricity, fuel, raw materials) and outputs (e.g., emissions, waste) across all the stages of the product or service. This data collection phase requires gathering detailed input and output data, including material flows, to build a comprehensive inventory. LCI data may be sourced from primary or secondary data, and the quality and completeness of LCI data are critical for accurate assessment. Accuracy at this stage is critical, as it forms the basis for meaningful analysis.

Stage 3: Life cycle impact assessment (LCIA)

Here, the raw inventory data is converted into environmental impact categories. These may include:

- Global warming potential

- Ozone layer depletion

- Eutrophication

- Ecotoxicity

- Human health impacts

The LCIA phase links physical flows to their potential environmental and societal consequences.

Stage 4: Interpretation

In this final stage, results are analyzed, cross-checked, and interpreted in the context of the original goals. Analysts identify improvement opportunities and areas of uncertainty. Interpretation is often iterative—findings may require a return to earlier stages for refinement.

How ESG software supports lifecycle assessments

With the growing complexity of environmental data and regulatory expectations, ESG software plays a key role in streamlining and scaling LCA implementation. These platforms can support organizations at every stage of the assessment.

Key benefits include:

- Data management: Centralizes and organizes LCA data from internal systems, suppliers, and partners

- Standardization: Ensures alignment with ISO and other environmental management standards

- Scenario modeling: Lets teams simulate alternative materials, designs, or processes to optimize impact

- Visualization and reporting: Generates reports and dashboards for internal stakeholders or external disclosure

Leading ESG platforms also support cradle to gate assessments, industry benchmarking, and automated updates when supply chain data changes.

Integrating lifecycle assessment into sustainability strategy

Incorporating LCA into broader business strategy isn’t just a technical exercise—it’s a strategic investment. A well-implemented LCA program enables companies to:

- Reduce costs through material and energy efficiency

- Minimize risk from environmental regulations and reputational damage

- Innovate more sustainably in product development

- Increase supply chain transparency

- Strengthen relationships with environmentally conscious investors and customers

For companies operating in different industrial sectors, LCAs provide a consistent methodology to compare environmental impacts across products and processes.

Making lifecycle assessment a business norm

To make the most of LCA, companies should embed it within product design cycles, procurement decisions, and sustainability reporting. Cross-functional collaboration is essential: sustainability teams must work closely with engineering, operations, procurement, and finance to embed LCA thinking into decision-making.

Challenges and solutions

While powerful, LCA can be time-consuming and resource-intensive. The biggest challenges include:

- Accessing high-quality primary data

- Managing the complexity of supply chains

- Ensuring consistent methodological approaches across products

These challenges can be mitigated by adopting ESG tools, investing in internal LCA expertise, and leveraging industry databases or sector-specific LCA models.

From insight to action

A lifecycle assessment provides a deep and actionable understanding of environmental performance across all the stages of a product’s life. It enables smarter choices, sharper sustainability strategies, and stronger stakeholder trust.