A product carbon footprint (PCF) is the total amount of greenhouse gas (GHG) emissions associated with a product throughout its lifecycle. This includes emissions from raw material extraction, manufacturing, transport, usage, and disposal. Measured in carbon dioxide equivalent (CO₂e), a PCF provides a clear, standardized picture of a product’s climate impact.

Unlike a corporate carbon footprint, which looks at emissions at the company level, a PCF zooms in on a specific item or product line. Whether it’s a smartphone, a litre of milk, or a tonne of steel, a PCF gives a product-level view of emissions, helping businesses and stakeholders understand the climate cost of the things we produce and consume.

A PCF is a form of product life cycle accounting that allows businesses to trace emissions through every stage of the value chain. Increasingly, it also supports the creation of a carbon footprint label, enabling companies to communicate climate impacts to customers in a standardized and transparent way.

As pressure mounts from regulators, investors, and consumers to prove environmental progress, product carbon footprints have become a key metric in sustainability strategies. They’re essential not only for tracking emissions but also for informing smarter business decisions across supply chains.

Why is a PCF measurement useful for businesses?

1. It can validate net-zero claims

Credible sustainability claims rely on accurate data—and PCFs provide that credibility. When a reporting company commits to net-zero targets or carbon-neutral products, having a detailed product carbon footprint ensures that emissions are calculated, accounted for, and verified using internationally recognized methodologies.

PCFs also help companies meet disclosure expectations from regulators, customers, and investors. As ESG regulations tighten and scrutiny of greenwashing increases, PCFs provide the defensible data needed to back up climate claims with confidence.

A product life cycle accounting approach ensures that net-zero claims aren’t based on assumptions or generic emissions factors but are grounded in the actual emissions associated with a specific product. This is essential for building trust with stakeholders and avoiding reputational risks.

2. It can inform decarbonization efforts

Product carbon footprints help businesses focus their decarbonization efforts where they matter most. A tonne of aluminium, for example, can have a carbon intensity ranging from 3 to 20 tonnes of CO₂e depending on how and where it’s produced. Without precise product-level data, businesses are left guessing where their biggest emissions lie.

PCFs make these emission differences visible. By breaking down emissions by lifecycle stage, companies can pinpoint carbon hotspots—such as energy-intensive manufacturing steps or high-emission raw materials—and take targeted action to reduce them.

They also provide a basis for benchmarking against industry peers, setting science-based targets, and tracking progress toward net-zero goals. Over time, businesses can use this data to justify capital investments, rethink sourcing strategies, or innovate in product design to create lower-carbon alternatives.

3. It can support market decision makers

In today’s carbon-conscious economy, product-level emissions data increasingly influence market decisions. Buyers, retailers, and trade finance providers use PCFs to compare emissions performance between suppliers or product variants. This allows them to make more informed procurement choices, select low-carbon alternatives, and allocate green finance more effectively.

For example, a retailer sourcing t-shirts from two suppliers may choose the one with lower PCF values to align with its sustainability goals. Similarly, financial institutions may prioritize lending to companies with well-documented, low-emission products in their portfolios.

As carbon pricing schemes and emissions-related tariffs grow in prominence, product carbon footprints can also influence cost structures and competitiveness. A verified PCF becomes not just a compliance tool, but a commercial advantage.

How does a product carbon footprint differ from a lifecycle assessment?

A product carbon footprint is a type of life cycle assessment (LCA), but with a specific focus: greenhouse gas emissions.

An LCA is a broader methodology that assesses multiple environmental impacts of a product, including water usage, air pollution, biodiversity loss, and resource depletion. A PCF, in contrast, zeroes in exclusively on carbon dioxide and other GHG emissions.

In practical terms, both use similar approaches—mapping production processes, gathering data, and applying impact factors—but a PCF applies only emissions factors to assess the climate change impact, measured in CO₂e.

PCFs are often the first application of life cycle assessment a company undertakes. They are simpler to implement than a full LCA, and offer the fastest route to understanding product-level environmental impact. They also act as a crucial input into full LCAs or environmental product declarations (EPDs), making them a strategic foundation for broader sustainability reporting.

| Aspect | Product Carbon Footprint (PCF) | Life Cycle Assessment (LCA) |

|---|---|---|

| Focus | GHG emissions only | Multiple environmental impacts |

| Metric | CO₂e (carbon dioxide equivalent) | Various (e.g. land use, water use, ozone depletion) |

| Scope | Cradle-to-gate or cradle-to-grave | Same, but broader analysis |

| Complexity | Simpler, faster to conduct | More complex and detailed |

| Use case | Emissions reduction, carbon labeling, net-zero strategies | Full environmental profiling, policy analysis |

How are product carbon footprints calculated?

Calculating a product carbon footprint involves several key steps—from defining your scope and collecting data to calculating emissions and allocating impacts. The process must align with internationally recognized standards like the GHG Protocol Life Cycle Accounting and Reporting Standard and, where relevant, ISO 14067. Software tools can streamline the PCF calculation process and improve accuracy.

Organizations such as the Carbon Trust and frameworks like the Global Reporting Initiative provide guidance and certification for product carbon footprinting.

Define your questions and goals

Before beginning, clarify the purpose of your PCF analysis. Examples include:

- Which part of the product lifecycle contributes most to emissions?

- Which life cycle stage has the greatest impact on the product’s overall carbon footprint?

- How does one product compare to another in terms of carbon footprint?

- What changes could reduce a product’s footprint most effectively?

- What data is needed for a carbon footprint label?

By establishing the questions your PCF must answer, you can focus your efforts on collecting the right data and applying the most relevant methodologies.

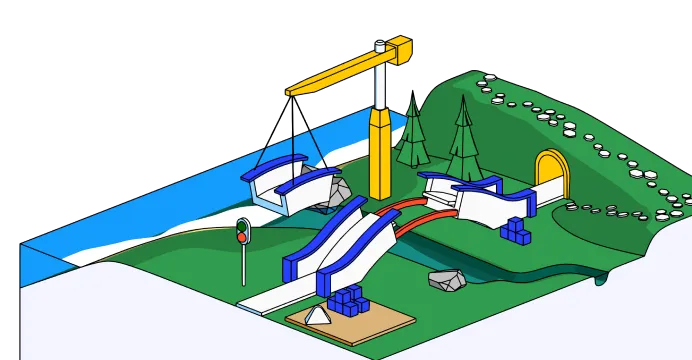

Define your product boundary: cradle to gate or cradle to grave?

Next, define the boundaries of the product lifecycle under consideration. Two common system boundaries are:

- Cradle to gate: Includes emissions from raw material extraction through manufacturing, ending at the factory gate.

- Cradle to grave: Includes all cradle to gate stages, plus distribution, use, and end-of-life treatment (e.g. landfill, incineration, or recycling).

A comprehensive PCF should consider the entire life cycle or product’s life cycle, including all stages from raw material extraction to end-of-life.

Cradle to gate assessments are useful for B2B manufacturers and when downstream data is limited. Cradle to grave is better suited to consumer goods or when the full lifecycle is under company control or influence. This approach captures total greenhouse gas emissions, including upstream and downstream emissions, downstream emissions, and all indirect emissions and other indirect emissions associated with the product.

The choice of boundary influences both the completeness and comparability of your PCF—and should be transparently disclosed when reporting results. Including all related emissions is essential for a complete assessment.

Collect data for every stage of the product lifecycle

Data collection is typically the most resource-intensive stage. You’ll need detailed inputs and outputs for each step of the product lifecycle. The more primary activity data you collect, the more accurate your PCF will be. High data quality is essential, and collecting detailed data for each process ensures precise and credible carbon footprint calculations.

Examples of primary data include:

- Litres of fuel used to transport raw materials

- Kilowatt-hours of electricity used in manufacturing

- Kilograms of material inputs per product unit

- GHGs emitted during chemical processes in production

When primary data is unavailable, secondary data from emissions databases or industry benchmarks can be used. However, secondary data reduces accuracy and should be flagged in the final assessment.

Data should be mapped across all relevant life cycle stages:

- Raw material extraction and processing

- Manufacturing and assembly

- Packaging

- Transport and distribution

- Product use phase (if cradle to grave)

- End-of-life treatment (if cradle to grave)

This structured approach reflects best practices in product life cycle accounting.

Calculate emissions at every stage

Emissions are calculated by multiplying each activity by its relevant emissions factor:

Activity data × Emissions factor = GHG emissions

Emissions factors indicate the CO₂e per unit of activity and are available from reputable sources such as the IPCC, DEFRA, or US EPA. Emissions are typically expressed in carbon dioxide equivalents, which standardize the impact of different greenhouse gases using global warming potential (GWP) values. GWP values, often derived from IPCC assessments, allow for the conversion of various greenhouse gas emissions into a single metric (CO₂e) for comprehensive climate impact assessment.

When products result in co-products or by-products, the GHG Protocol outlines allocation rules to fairly divide emissions between outputs. Common methods include:

- Mass-based allocation: Emissions divided by product weight

- Economic allocation: Emissions divided by product value

- System expansion: Emissions credited or offset through avoided impacts of co-products

Fossil fuels and the act of burning fossil fuels are major contributors to product carbon footprints. More than half of global warming is attributed to carbon dioxide emissions from burning fossil fuels.

For GHG Protocol alignment, companies should also calculate:

- Total emissions per functional unit (e.g. kg of product, per item)

- Emissions breakdown by lifecycle stage

- Percentage of emissions based on primary vs secondary data sources

The final results can also inform the development of a carbon footprint label—a growing trend among consumer goods companies and retailers seeking to communicate product impact to customers.

How a carbon management tool can support your PCF calculation

Conducting product carbon footprint calculations manually is time-consuming, especially across multiple product lines, geographies, or suppliers. This is where carbon management software plays a transformative role.

Centralized data collection and integration

Modern platforms integrate with ERP, procurement, and manufacturing systems to automate data collection. This reduces errors, increases data granularity, and allows companies to capture more primary data from across the product life cycle.

Automated emissions calculations

These tools include pre-loaded databases of emissions factors and apply them accurately to input data. The result is faster, more consistent, and audit-ready PCF results that align with standards like ISO 14067 and the GHG Protocol.

Scenario modeling

Many tools allow companies to run simulations to see how design or supply chain changes would affect the product carbon footprint. For example, switching from virgin plastic to recycled material, or changing a supplier’s energy mix, can be modeled and compared directly.

This allows businesses to weigh the carbon benefit of potential changes before implementation—supporting more strategic decarbonization decisions.

Audit-ready reporting and verification

Carbon management tools store detailed records of inputs, assumptions, and calculations. This makes it easier to verify results for internal use, investor confidence, or third-party certification.

They also support the creation of standardized outputs such as:

- Product Carbon Footprint reports

- GHG Protocol-aligned disclosures

- Carbon footprint labels for packaging or online listings

Scalable insights

Once PCF models are developed, businesses can scale their methodology across hundreds of SKUs, suppliers, or locations. This capability is essential for large manufacturers or retailers seeking portfolio-wide carbon insights.

With version control, automated updates, and data governance features, carbon management platforms reduce the complexity of product life cycle accounting—and help companies turn emissions data into action.

Building a competitive edge through product carbon footprinting

Understanding and managing your product carbon footprint is not only essential for compliance and reputation—it’s a growing source of strategic advantage. As stakeholders increasingly expect transparency, and as carbon impacts become embedded in procurement and financing decisions, PCFs offer a foundation for smarter, lower-emissions growth.

Product-level carbon data enables companies to:

- Prioritize investments in decarbonization where they’ll have the greatest impact

- Equip sales and procurement teams with emissions performance data

- Communicate with confidence through carbon footprint labels and net-zero claims

- Meet upcoming sustainability disclosure requirements with clarity and speed

In short, PCFs bridge the gap between sustainability ambition and execution. By embedding product life cycle accounting into their core operations, businesses can not only reduce their emissions—but also build trust, open new markets, and future-proof their value chains.

If your company is ready to take its carbon footprint analysis to the next level, now is the time to get started—before the next procurement cycle, investor query, or regulatory deadline arrives.