The complexity of calculating emissions in UK supply chains

The UK is a net importer, meaning many of the goods consumed domestically are produced abroad. This creates significant challenges for carbon accounting, as the associated greenhouse gas (GHG) emissions—particularly Scope 3 emissions—are difficult to track and verify.

Yet these indirect emissions often make up the largest share of a business’s overall carbon dioxide equivalent (CO₂e) footprint. Calculating them is essential for businesses aiming to manage their climate-related risks, reduce emissions across their full value chain, and ultimately achieve net zero emissions.

The rigor, transparency, and standards-based approach required for carbon accounting is comparable to financial accounting, where accuracy and comparability are critical for reliable ESG and GHG emissions reporting.

What the data says: UK sustainability leaders speak out

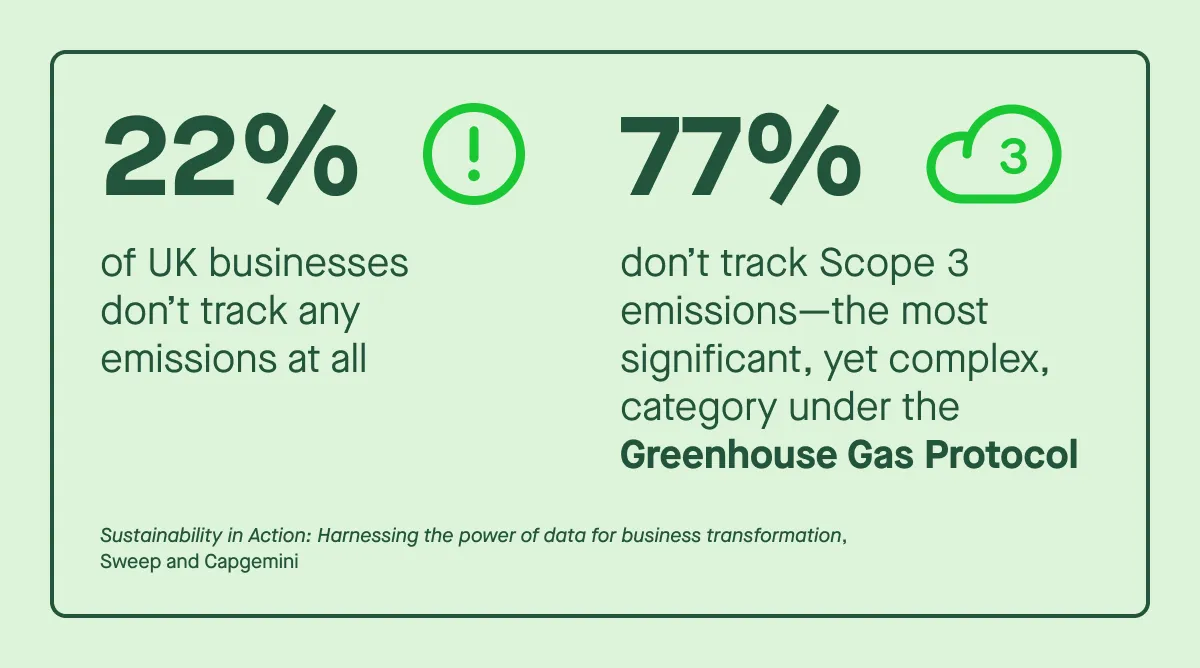

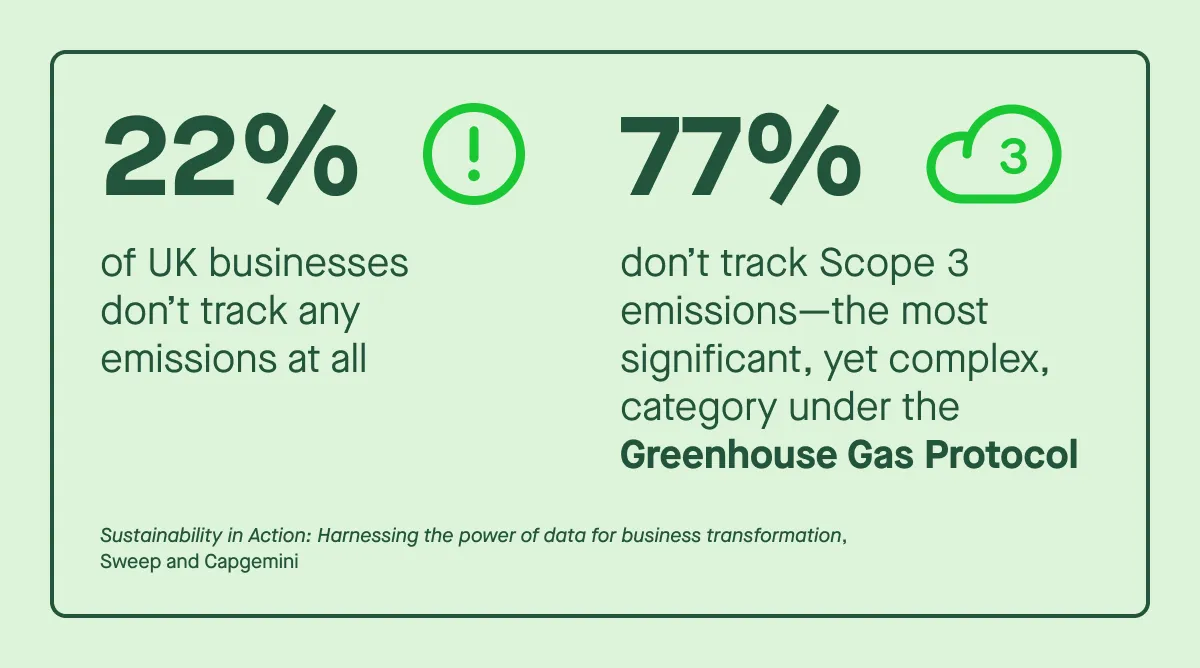

Research from Sweep and Capgemini, published in the report Sustainability in Action: Harnessing the power of data for business transformation, surveyed over 550 sustainability leaders across four major economies.

The findings show UK businesses are feeling the heat:

- Nearly half (49%) say they spend too much time gathering and organising data—yet one in three still feel their data isn’t comprehensive enough.

- 22% of UK businesses don’t track any emissions at all, and 77% don’t track Scope 3 emissions—the most significant, yet complex, category under the Greenhouse Gas Protocol.

- 54% of sustainability managers spend at least four hours a week consolidating data—and 19% spend more than eight hours.

The research underscores a clear challenge: even as UK businesses acknowledge the urgent need to act on climate change, the lack of efficient, accurate data is holding them back. To get to net zero emissions, businesses must be able to calculate GHG emissions across all scopes using transparent, repeatable carbon accounting principles—something that requires the right data infrastructure and tools.

Four key carbon accounting challenges in UK retail and manufacturing

Companies across the UK are under growing pressure to understand, report, and reduce their carbon emissions—but the complexity of doing so is staggering. For businesses operating across supply chains, product ranges, and industrial sites, the barriers to accurate carbon accounting are both technical and organisational.

Take Butternut Box, a fast-growing DTC pet food company delivering fresh, human-grade meals to thousands of customers across the UK.

Or Wickes, a major home improvement retailer with a national store network and thousands of SKUs—from nails and paint to fully fitted kitchens.

Or SSE, one of the UK’s largest electricity network and energy infrastructure companies, supporting renewable generation and the transition to net zero.

These companies operate in very different environments—but they share common hurdles when it comes to measuring and managing their greenhouse gas (GHG) emissions.

Carbon accounting relies on methodologies such as scope categorization and data collection techniques to accurately measure greenhouse gas emissions. Below, we explore four of the most pressing carbon accounting challenges facing UK retail and manufacturing—and how carbon accounting platforms are helping companies meet them with confidence.

1. Tracking greenhouse gas emissions across complex, global supply chains

Most UK companies have limited visibility into the environmental impact of their upstream suppliers. Tracking supply chain emissions is essential for understanding the organization’s greenhouse gas impact across all scopes, as it encompasses both direct and indirect emissions.

For both retailers and manufacturers, emissions data is often fragmented, inconsistent, or missing entirely—especially for Tier 2 and Tier 3 suppliers. Traditional spreadsheet-based methods are no longer sufficient to manage this level of complexity.

Without accurate data, it becomes difficult to measure emissions effectively, and incomplete data increases the risk of blind spots in carbon accounting. As a result, carbon accounting lacks the integrity needed to inform decisions or meet regulatory expectations.

In practice:

- For Butternut Box, sourcing ingredients like meat and vegetables from farms across the UK and Europe introduces variability in emissions due to differences in agricultural practices, logistics, and supplier reporting standards. Changing supply routes, packaging formats, and third-party processors all add layers of complexity.

- Wickes works with a vast supplier base, including global manufacturers and local producers. Tracking the emissions impact of each supplier—especially when emissions factors vary significantly by geography and manufacturing method—requires far more than annual averages or industry assumptions.

The solution: Carbon accounting platforms can integrate supplier data from multiple systems, standardise emissions factors, and support the collection of primary data directly from vendors.

These tools help companies map out scope 3 emissions across their value chains, assign appropriate estimation methods, and improve data quality over time.

Each product typically has its own unique supply chain, raw materials, and lifecycle emissions. Accurately calculating product-level emissions requires detailed bill-of-materials (BOM) data, supplier information, and robust lifecycle analysis. But many legacy systems in retail and manufacturing were never built to support this level of granularity, and generic carbon estimates risk undermining credibility.

In practice:

- Wickes carries tens of thousands of product lines—ranging from lightbulbs to bathrooms—each with a different materials mix, manufacturing process, and transport profile. Without automation, deriving individual emissions data per SKU is virtually impossible.

- SSE generates and distributes energy through a range of facilities, each with distinct technologies, inputs, and operational patterns. Calculating the emissions intensity of these operations—particularly at the product or service level—requires detailed data that goes beyond high-level averages.

The solution: ESG software platforms provide product carbon footprint (PCF) and lifecycle assessment (LCA) tools and integrate with procurement or ERP systems to link emissions to specific products. Different carbon accounting methods, such as hybrid methods that combine spend-based and activity-based approaches, can be used to improve accuracy, confidence, and compliance with global standards.

Spend-based and activity-based methods can be applied in tandem, allowing companies to model product-level emissions even when supplier data is incomplete.

The spend based method estimates emissions by multiplying the financial value of purchased goods or services by an appropriate emission factor, which is particularly useful when detailed activity data is unavailable. This approach helps estimate the impact of product-level activities on the company’s greenhouse gas emissions, but may have limitations in accuracy compared to activity-based methods.

3. Making sustainability data actionable for strategic decisions

Even when data is collected, many businesses struggle to translate it into decisions. Senior leaders and sustainability teams need real-time dashboards, predictive modelling, and site-level insights to shape procurement, operations, and investment. Without those tools, emissions reporting becomes a compliance exercise—rather than a lever for transformation.

In practice:

- SSE previously collected data manually, once per year, via spreadsheets and email. This made it difficult to identify emissions hotspots or act in real time. Their auditors found it increasingly difficult to verify the data, which posed a growing assurance risk.

- Wickes needs emissions data to inform product sourcing, store energy usage, and distribution centre operations. But without integrating these data sources, identifying cost-effective emissions reductions becomes a manual and inefficient task.

The solution: Modern carbon accounting platforms centralise emissions data, present it in intuitive dashboards, and allow users to model scenarios—such as how switching a supplier or transport mode might affect the company’s total footprint.

These insights help businesses make faster, smarter decisions that align sustainability with operational goals. They can also help companies identify and manage climate related risks by providing insights into how climate risks impact operations and strategic decision-making.

4. Responding to regulatory and investor pressure

Carbon accounting is no longer a voluntary exercise for many organisations. Regulatory frameworks like the CSRD (Corporate Sustainability Reporting Directive), SECR (Streamlined Energy and Carbon Reporting), and TCFD (Task Force on Climate-Related Financial Disclosures) are becoming mandatory for many UK firms. At the same time, investors are demanding clearer, auditable climate disclosures. Many companies lack the systems and confidence to meet these growing expectations.

In practice:

- Butternut Box’s investors have ESG mandates that require portfolio companies to align with frameworks like the Carbon Disclosure Project (CDP) and Science Based Targets initiative (SBTi). While SBTi provides methods for setting emissions reduction targets aligned with climate science, it is not a carbon accounting framework itself. The company must deliver transparent, standardised emissions data—often at short notice.

- SSE is actively preparing for CSRD compliance due to its operations in both Great Britain and Ireland. By creating a clear, auditable baseline of its emissions data and mapping gaps against expected reporting requirements, it is able to strengthen internal governance, ensure data consistency, and lay the groundwork for full compliance with new regulations.

The solution: ESG software platforms help companies manage compliance with reporting frameworks by aligning their data collection and reporting processes with global standards. They enable audit trails, documentation, and version control—so that companies can report with confidence and respond to investor demands quickly and accurately.

Carbon accounting software – common challenges solved

Carbon accounting software is essential for companies looking to measure, report, and reduce their GHG emissions. It helps organisations align with global standards while managing the complexity of carbon data across operations and supply chains.

Key capabilities include:

- Automated data collection: API integrations, IoT devices, and smart meter data replace manual inputs. Software can automatically apply the correct emissions factor to different data sources for accurate GHG accounting and measurement of greenhouse gases.

- Scope 3 modelling: Advanced platforms offer supplier surveys, spend-based estimations, and lifecycle tools to assess value chain emissions.

- Product-level tracking: Enables granular analysis down to recipe or SKU level. These tools help measure emissions of greenhouse gases and track value chain emissions produced at each stage of the product lifecycle. They also measure carbon emissions across different scopes and sources, supporting comprehensive emissions management.

- Dashboards and alerts: Real-time insights and visualisations support rapid, informed decisions, helping companies understand their contribution to global warming and identify opportunities for reducing emissions by tracking progress toward sustainability goals.

- Audit readiness: Built-in logs and templates align with GHG Protocol, CSRD, and SBTi requirements.

- AI-powered forecasting: Predict future emissions based on production plans, energy sourcing, or logistics shifts.

Choosing the right carbon accounting software

Accurate carbon accounting is essential for companies aiming to understand their corporate carbon footprint, meet evolving carbon reporting requirements, and reduce their climate impact.

Choosing the right carbon accounting software means finding a solution that aligns with established carbon accounting frameworks like the GHG Protocol, and supports your journey toward net zero.

When evaluating ESG platforms, consider the following:

Scalability – Can the software scale across multiple sites, regions, and product lines—handling everything from direct emissions to complex Scope 3 emissions such as upstream logistics and supplier activity?

Customisability – Does it support flexible carbon accounting methodologies, including the ability to apply region-specific emission factors and tailor models to internal KPIs?

Integration – Will it integrate with your core systems—such as your ERP, data warehouse (e.g. Snowflake), or supplier management platforms—for seamless, automated data flow?

Auditability – Are data sources, assumptions, and calculation methods fully transparent and traceable, ensuring compliance with regulatory frameworks and investor expectations?

Support & Onboarding – Does the provider offer expert guidance during setup, and help optimise performance over time?

Cost Savings – Can the platform help identify emissions hotspots and operational inefficiencies, leading to meaningful cost savings through smarter energy use, reduced waste, and more efficient supply chains?

Carbon accounting FAQs

What is carbon accounting?

A system for measuring greenhouse gas (GHG) emissions, including carbon dioxide, methane and nitrous oxide. Note that methane emissions are a significant source of direct greenhouse gas emissions, particularly from fugitive emissions in manufacturing.

Emissions are expressed as carbon dioxide equivalent (CO2e), which is the standard carbon accounting measure used to quantify the impact of different greenhouse gases on global warming.

Why is carbon accounting important?

- It helps calculate a company’s total carbon footprint, also known as corporate carbon footprints, by measuring and categorizing greenhouse gas emissions across Scope 1, 2, and 3 to quantify overall environmental impact.

- It enables organisations to reduce emissions and achieve emission reductions, with a focus on quantifying, monitoring, and verifying these reductions as part of sustainability strategies and environmental integrity.

- After implementing reduction strategies, organizations may still have residual emissions, which are the remaining greenhouse gases that must be offset to achieve carbon neutrality, as addressed by standards such as PAS 2060.

- It supports compliance with global greenhouse gas accounting standards like the Greenhouse Gas Protocol.

Corporate carbon accounting involves a comprehensive process of measuring and managing a company’s greenhouse gas emissions across all scopes, supporting sustainability strategies and stakeholder engagement.

What are the different types of emissions?

- Direct emissions (Scope 1): from owned or controlled sources (e.g. fuel combustion).

- Indirect emissions (Scope 2 & 3): from purchased energy and upstream/downstream activities. Scope 3 includes other indirect emissions from the value chain, such as supplier operations, product use, and other upstream and downstream processes.

- Most companies find that supply chain emissions (Scope 3) make up the largest share of their GHG emissions. Calculating GHG emissions requires detailed methods and standardized protocols to ensure accuracy, compliance, and reliable reporting.

- Fugitive emissions: unintentional greenhouse gas releases—such as leaks from equipment, pipelines, or industrial processes

What are the different methods of carbon accounting?

There are three main methods of carbon accounting:

- Spend-based method: Estimates emissions by multiplying the cost of goods or services by an average emissions factor.

- Activity-based method: Uses specific data (e.g. litres of fuel used, kWh of electricity) to calculate emissions with higher accuracy.

- Hybrid method: Combines both spend- and activity-based data to improve coverage and precision, especially when full activity data isn’t available.

|

Want to get on top of your company’s GHG emissions?

Start using Sweep today to understand and manage your greenhouse gas emissions, achieve compliance with key regulations, and drive progress towards your support sustainability goals.

Book a demo